After a very informative conversation with Jim, the author of several of the comments on this blog, it has become obvious that some additions to the websites and this blog are in order. First, where and how to get the sand needed to put together a small slow sand filter.

Links to sand suppliers:

Under “A variety of applications”, this website says they have sand that will work for “water filtration and purification”. I have not checked this one out closely yet. . . . . :

the Cemex company

Standard Sand and Silica company in Florida

Lane mountain sand company in Washington state

Red Flint sand company in Wisconsin

target sand company in Canada and USA

A subsidiary of the QUIKRETE® Companies

Unimin (this link is to the company’s locations page) A local supplier here in Seattle is Salmon Bay Sand and Gravel.

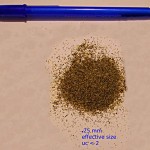

Manufacturers Mineral Company in Renton, WA (no website found) they have a .25 mm effective size sand called “TB Sand”.

1215 Monster Rd SW

Renton, WA 98057

(425) 228-2120

These suppliers may not sell directly to individuals, so it will be necessary to find a local sand and gravel company or hardware store to order the sand for you. The large hardware stores may be able to order it for you if you have the supplier’s name and the product description. Alternatively, one could dig sand from a riverbed, (taking extreme care to avoid destroying ecosystems), wash it, sterilize it, dry it and then run it through sieve to size it appropriately.

If you live in a place where there is lots of sand readily available, this may be the best option. . . however it will be extremely time consuming, one would have to purchase the proper sieve devices which would likely be super expensive. I have already tried using un sized sand directly from the ground. It works but not very well. In an emergency situation, sifting sand through a makeshift sieve would probably work and would be able to provide safe water, but it would not be ideal.

Can “play sand” be used for a slow sand filter? Yes, but it is difficult to wash and contains lots of silt and furthermore the sizes of the grains vary widely. As a result the filter will plug up very quickly. Can mason’s sand be used? Maybe, depending on what is in it. Again, the effective size and uniformity coefficient may not be suitable for filtration purposes. What about sand from the beach? Probably not, unless the sand is washed and sterilized which would likely cost WAY more than just buying filter sand. If the “beach” is next to salt water, then the sand would be nearly impossible to clean. If the “beach” is contaminated then the sand would also be contaminated. If the “beach” is on fresh water and contamination is minimum, then the sand may be usable, but be aware that there may be horrific contamination from anywhere. The sand would need to be washed, and then heated to very high temps to be safe.

Much more info later as I get time. . . . .